Corrugated roof sheets have been a trusted roofing solution for kiwi homes for decades now. Across the country, homes, houses, commercial buildings, farm sheds and more have used corrugated iron in their builds. Versatile and cost-effective, it’s one of the best choices on the market.

While it’s a tried-and-true material, buying the right sheets is not always as straightforward as it seems. If you’re planning a roofing reno, a new build, or something in between, it pays to be cognisant of potential pitfalls that may impact the quality or longevity of your build.

Here are some common mistakes people make when selecting corrugated roof sheets, for their homes, and how you can avoid them.

Choosing the wrong material or grade of corrugated roof sheet

The first thing you’ll find when selecting your corrugated roof sheets is that there seem to be a lot of options.

The term “corrugated iron” is often used loosely both in industry and in common speak, but today’s roofing sheets can be made from different materials: galvanised steel, zincalume, aluminium, or pre-painted coated steels. Each option has its own strengths.

Galvanised corrugated iron is affordable and widely available but may not last as long in coastal or high-moisture environments.

Zincalume or aluminium-zinc coated sheets provide better resistance to the elements but are costlier.

Pre-painted sheets add style and durability but require careful colour selection to suit the environment and build.

If you choose the wrong type of corrugated iron for your region or project, you might face premature rust, fading, or expensive replacements much sooner than expected – or desired!

Getting the wrong measurements

It’s surprisingly easy to miscalculate the amount of roofing you need, as roofers may tell you!

Corrugated roof sheets are designed to overlap to reduce the chances of water ingress, making the overall coverage area less than the sheet width. If you forget to account for these overlaps, you‘ll find yourself short of material on installation day.

However, ordering too much corrugated iron adds unnecessary cost and storage headaches. That’s why precision matters, so measure carefully, factor in overlaps, and double-check with your supplier or builder before placing an order. And remember the tradies’ mantra: measure twice, cut once!

Ignoring local climate conditions

Your roof is your first line of defence against the elements, and climate plays a huge role in how corrugated roof sheets perform over the lifespan of your roof. For example:

In coastal areas like Hawke’s Bay, Auckland or Bay of Plenty, salt spray accelerates corrosion in standard galvanised sheets. You’ll need a higher-grade coated steel or aluminium option that’s resistant to rust.

In high rainfall regions like Waikato or Manawatu poor water runoff can cause leaks if the sheets are installed with too shallow a pitch or lack the overlap required.

In hot regions with high sun exposure like the Canterbury Plains, choosing a dark-coloured corrugated iron might mean extra heat absorption and make buildings uncomfortable during the hot summer months.

Warranty and certification

Reputable manufacturers back their corrugated roof sheets with warranties covering coating performance, structural integrity, and corrosion resistance. However, cheaper imports, unbranded products or second-hand retailers often lack these guarantees, so it’s important to choose a retailer that stands by the quality of their product

If you’re feeling tempted by a corrugated roof sheet TradeMe bargain, remember that your roof needs to be a long-term investment. If your roof fails over time due to poor-quality corrugated iron, it’ll cause water damage, mould, and structural issues that will end up hurting your wallet far more than your initial savings were worth!

Poor planning around installing your corrugated roof sheets

Even if you’ve bought quality corrugated roof sheets, problems can still arise when it comes to installation time. Ordering corrugated roof sheets that are too long can make transport and handling difficult, while sheets that are too short lead to unnecessary joins.

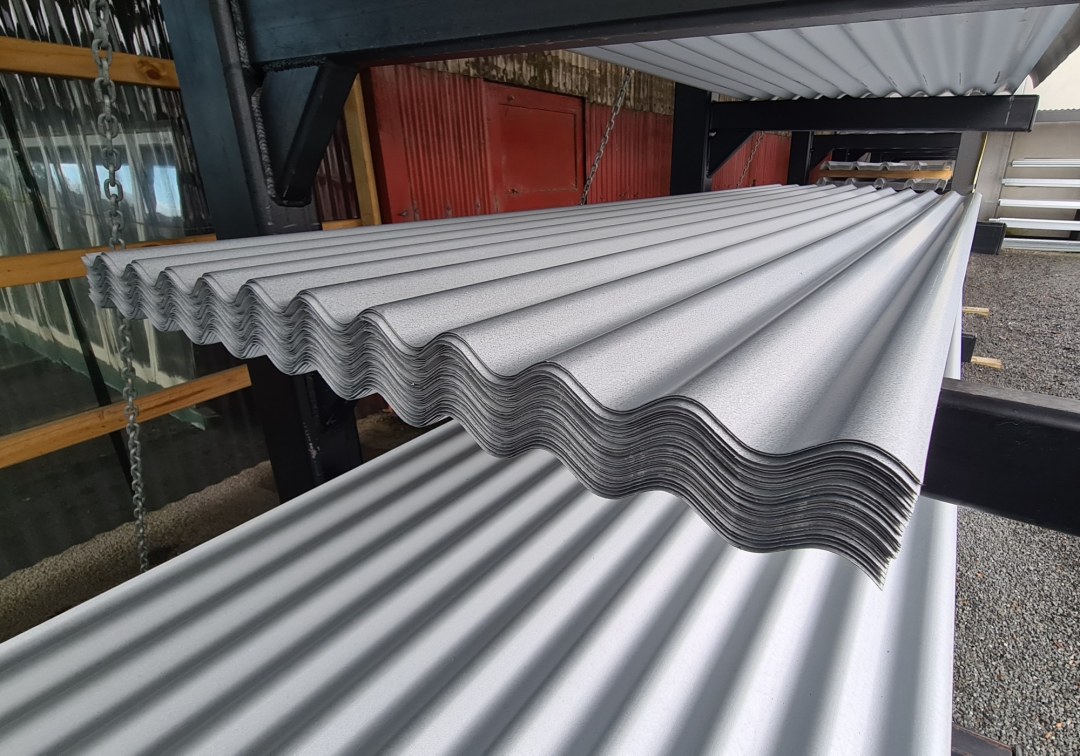

Storage before installation is often overlooked. If corrugated iron is left stacked in damp conditions or exposed to the elements, moisture can become trapped between sheets, leading to “white rust.” Sheets should always be stored off the ground, under cover, and with good airflow.

Where should I buy my corrugated roof sheets from?

There are many businesses in New Zealand competing for your business, and choosing the right one can mean saving time and energy, as well as saving yourself a hassle!

Demolition Traders

Demolition Traders in Hamilton is one of New Zealand’s largest privately-owned suppliers offering both new and recycled building materials

Website: demolitiontraders.co.nz

Email: info@demolitiontraders.co.nz

Phone: 0800 DEMOLITION

Metalcraft Roofing

Metalcraft Roofing is one of New Zealand’s largest and most established privately owned roofing providers.

Website: metalcraftgroup.co.nz

Email: orders.akl@metalcraftroofing.co.nz

Phone: 09 273 2820

The Roofing Store

The Roofing Store is a leading provider of high-quality steel roofing and cladding solutions across New Zealand

Website: theroofingstore.co.nz

Email: orders.manukau@theroofingstore.co.nz

Phone: 09 277 2717 wiribiz.org.nztheroofingstore.co.nz

TopSteel

TopSteel is a New Zealand supplier offering quality and competitively priced corrugated roofing sheets, catering to roofing, fencing, and cladding needs

Website: topsteel.co.nz

Email: topsales@topsteel.co.nz

Phone: +64 21 194 2737